What happens when you rebore an engine? AMAC Engineering are Northallerton and North Yorkshire engine rebuild specialists. If you are considering an engine re-bore, we look at the purpose of engine rebores and when reboring of an engine is required.

Boring Your Engine

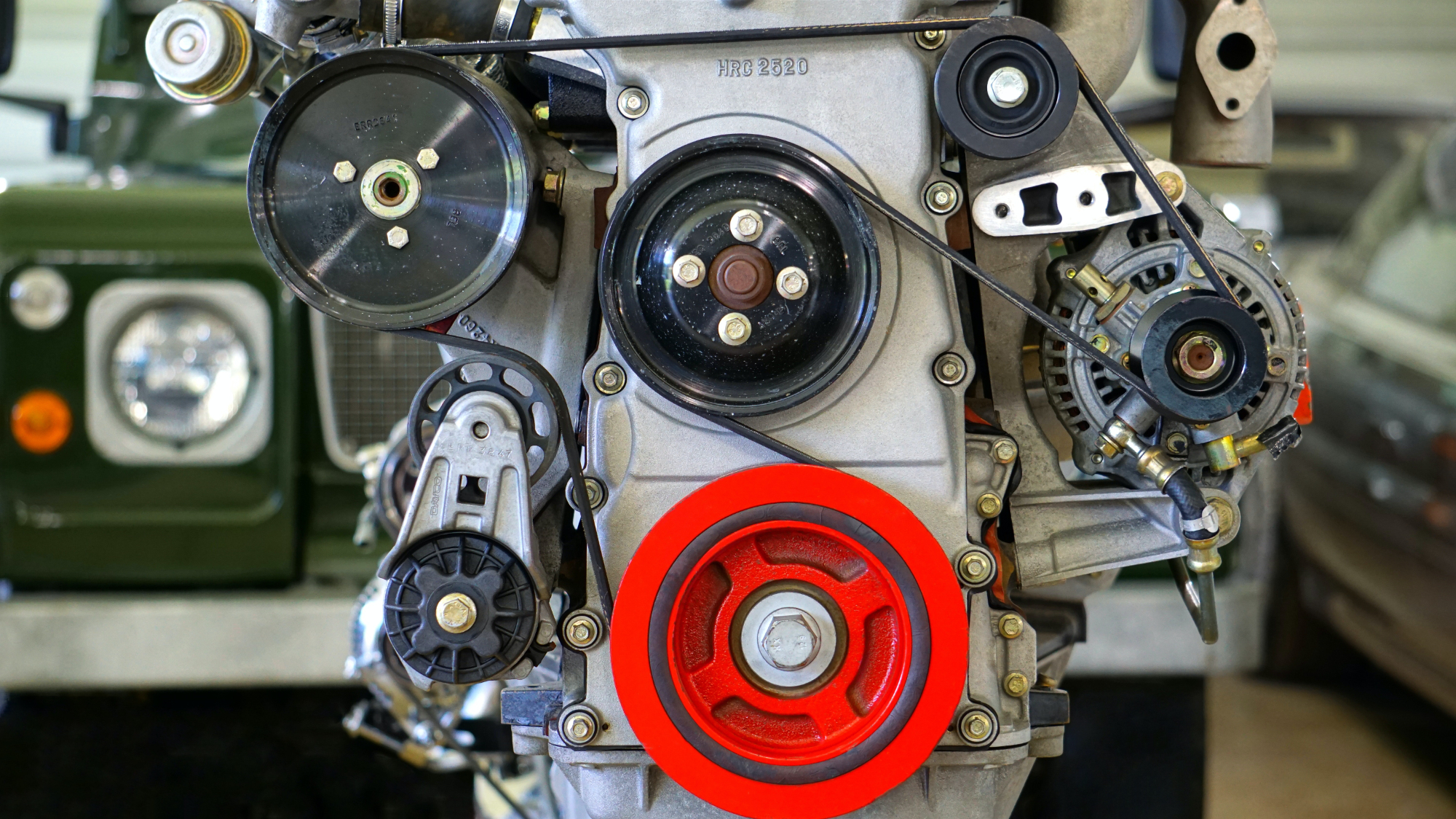

Machines are used to broaden and taper the cylinders during boring an engine. Boring an engine can improve performance by changing the engine's displacement, which increases horsepower and torque. Engine displacement is the collective volume of all the pistons swept inside the engine's cylinders.

High displacement engines pull in more of the air and fuel mixture every revolution, producing more potent combustion, which affects how much fuel a cylinder draws in to generate power. Engine displacement is a key factor in influencing the amount of horsepower and torque and fuel efficiency that your engine generates.

Generally speaking, your engine can produce more power the more displacement it has. Engine displacement may be calculated mathematically using the engine displacement formula = π/4 x bore² x stroke x number of cylinders. Smaller displacement may lead to better fuel economy.

Displacement is simply one element that affects your engine's output. Fuel supply, valvetrain design, forced induction, and ignition systems are further considerations. Vehicle taxes in certain nations are determined by the size of the engine.

As mechanics are restoring engines, boring is also done. Engine cylinders deteriorate over time as a result of friction loads that cause wear and tear; boring out engine cylinders helps clean them of debris that can accumulate over time.

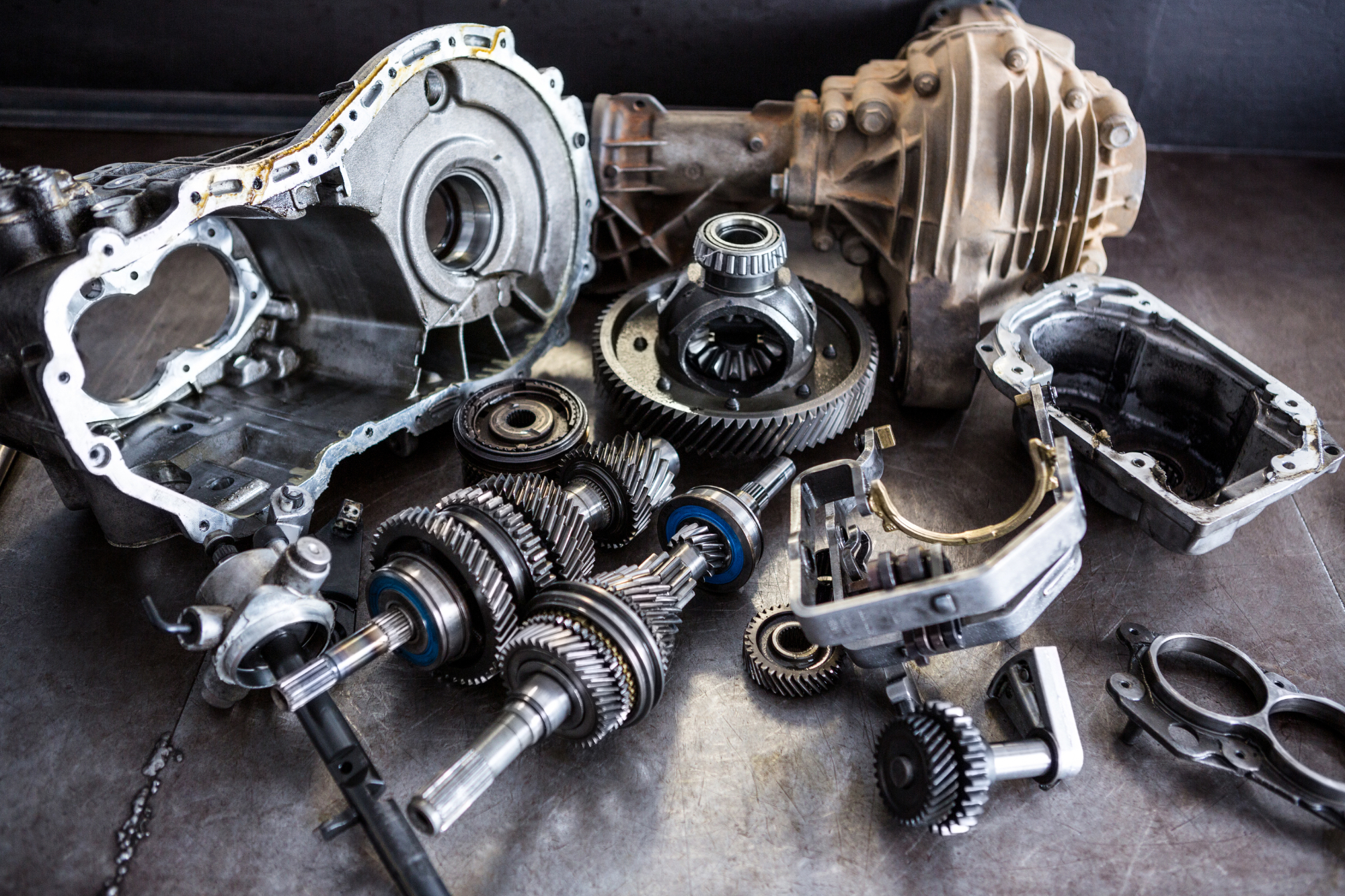

It is recommended to leave the bore of an engine to experienced mechanics because poor work can cause serious issues, such as engine knock. Another way to increase the displacement of an engine is to stroke it. While engine stroking permits a larger displacement than boring, it also necessitates extreme care in selecting the proper auto accessories and parts.

A mechanic will change the piston's travel distance within the cylinder bore during engine stroking. A mechanic can enhance engine displacement by lengthening the piston's path within the cylinder. By lengthening the crankshaft arm or lever, starting the engine also increases torque.

Contrary to what some other commenters have suggested, the longer moment arm at 90 degrees rod to crank angle does provide more torque per unit of cylinder pressure. Engine boring increases displacement, which allows for higher torque output because of the capacity to swallow and burn more fuel.

The mean piston speed is higher, the rate of acceleration/deceleration near TDC and BDC is higher, and the side thrust forces perpendicular to the cylinder bore are higher; these increased stresses may necessitate the use of stronger parts or a reduction in the engine's maximum RPM in order to prevent overstressing and breaking of components.

Read More About Engine Rebuild Services In Northallerton And North Yorkshire

Why Should An Engine Be Overhauled?

What Is The Purpose Of Engine Refurbishment?

What Improves Engine Performance?

What Engine Modifications Make A Car Faster?

What is the Purpose of Engine Rebores?

Engine cylinders are exposed to stress and wear over time, and as a result, they get worn or damaged to the point where the piston rings cannot form a good seal, which worsens performance by increasing oil consumption and lowering efficiency.

Furthermore, excessive wear increases the possibility of a number of other problems, including fractured piston rings. So, it's crucial to keep cylinder bores in good shape and within the required diameter range. A just sharpened cylinder bore seems considerably rougher than a worn cylinder bore to the unaided eye. Honing produces a scratched surface with a clear crosshatch design.

In contrast, a used cylinder may seem smooth and polished with considerably less crosshatch evident, depending on how worn out the cylinder is. The profile of a newly sharpened cylinder wall exhibits several small peaks and troughs. During the honing procedure, the abrasives carve out valleys from the metal, and the peaks signify the highest point on the surface that will come into contact with the rings.

Large, sharp peaks won't last long after the engine is going since the rings will begin to break in and progressively shear off the peaks' tops. When the tallest peaks are eliminated, the "mountains" soften, creating a "plateau" look. This improves the rings' bearing area and makes it simpler for them to travel across the surface while riding on an oil coating that is retained in the valleys.

One ring maker claims that once the rings have been installed, wear essentially stops since they are no longer in direct physical touch with the cylinder wall and are instead sustained by a thin oil coating. Due to this, the ideal cylinder bore surface should essentially mimic this situation.

By employing the appropriate honing technique, you can produce a surface finish that enables the rings to seat fast with little wear and that will hold the optimum amount of oil so the rings are properly lubricated.

An engine's capacity may be increased to improve its power; however, this is a rather labour-intensive operation and requires much planning and study beforehand, unless you want to end up having to change your plans midway through the project. The cylinders are the heart of every engine, as they are where compression and combustion occur.

A one-litre displacement engine has cylinders of the same capacity (0.25 litres per cylinder in a 4-cylinder engine - this is filled with fuel and air). After that, the mixture is squeezed to prepare it for ignition and combustion inside the cylinder. Another key component of an engine is the compression ratio, which if too high can induce engine knock, also known as detonation.

As a result, it's critical to consider while increasing an engine's cylinder capacity. In general, the more you start with, the more power you'll acquire. If you have an aluminium block, you might be able to fit a little thinner liner, and your only other choice would be a stroker kit, which is something; clearly, a larger cylinder diameter requires a larger diameter piston.

Despite the fact that it may appear simple, you must drill out while maintaining concentricity, make sure they are machined to the same deck height, and make sure they are parallel to the crank centre line. A quality jig borer will be exactly to within a thousandth and then completed with precise honing, but attempting to perform a rebore yourself with a mill would result in chatter marks and not a good enough finish.

Remember that the cylinder wall must always be carved with a crosshatch pattern to aid in bedding in the piston rings and preserve a proper compression ratio. Blocks are frequently comparable to 1600, 1800, and even 2000 engines, however, the internal cylinder diameter varies.

The cylinder capacity of these engines may be successfully increased by reboring them to a bigger size and inserting pistons from the larger engine. The form, size, and profile of the pistons are occasionally the sole distinction between a smaller engine and a bigger engine.

If you haven't done your research, don't be surprised if you can't find pistons that match your chosen rebore dimension after the cylinder has been rebored. Get the chamber volume measurements after the cylinder has been rebored. Machine the heads to balance these measurements while also removing any material required to get the compression ratio right.

When is the Reboring of an Engine Required?

Lift the head, make a visual check, feel with your fingernails, and measure the bore to determine whether boring is required. When the cylinder is damaged beyond what honing can repair, or is irregular, or oval, reboring an engine is required: overheating, flat patches in the ciliary wall or a diameter that is not within specification can all cause this.

Always take measurements throughout the engine's stroke to ensure it is in good working order. Before allowing an engine to be bored, make sure you have a set of oversize pistons and instruct your engine builder to bore the engine according to the pistons' specified dimensions.

If you are considering an engine re-bore in Northallerton or North Yorkshire, our engine rebuild specialists can improve your car performance. Contact us today.